|

ABC,

RINGED, and LAPPED refer to piston/cylinder assemblies.

|

|

ABC has become

the most common type of piston/cylinder arrangement for smaller

engines in recent years. Some ABC type engines actually use

nickel plating instead of chrome for the wear surface. Nickel

is less expensive because it is more environmentally friendly,

however chrome has a much slicker surface for less friction.

The

ABC type piston and cylinder are manufactured as a matched

set,

you can not purchase a piston or cylinder separately.

The only exception to this is if the piston has a ring

like with some HP and WEBRA engines.

|

|

|

ABC,

ABN and AAC engines all fall under the same design category

ABC Ringed will not have the "pinch" or tight spot

at the top of the stroke.

|

|

ABC

|

ABN

|

AAC

|

|

A -- refers to Aluminum Piston

|

A

-- refers to Aluminum Piston

|

A

-- refers to Aluminum Piston

|

|

B

-- refers to Brass Cylinder

|

B

-- refers to Brass Cylinder

|

A

-- refers to Aluminum Cylinder

|

|

C

-- refers to Hard Chrome plating

|

N

-- refers to Electroless Nickel plating

|

C

-- refers to Hard Chrome plating

|

|

|

You

can tell an ABC engine by looking in the exhaust port.

The cylinder will be brass and the inner wall of the

cylinder will have chrome plating.

The

piston will be aluminum color and usually has oil retention

grooves cut into it.

ABC engines

have a tight fit so the oil film is easily wiped away

with each stroke.

|

|

|

An

ABN engine is a little more difficult to distinguish.

The cylinder is completely plated inside and out with

Nickel so it may appear to be Steel. No brass is showing.

The piston will be aluminum color and usually has oil

retention grooves cut into it as shown above. On this

example the top flange has been machined exposing the

brass.

A side

note...

The small notch cut into the flange is actually there

for location purposes during manufacturing. It was not

placed there to align the sleeve the the crankcase.

It has been utilized for this in some engines, but it

is not necessary for it to be "pin located"

in the crankcase.

|

|

|

You

can tell an AAC engine by looking in the exhaust port.

The cylinder will be light aluminum color and the inner

wall of the cylinder will have chrome plating. The piston

will be aluminum color and usually has oil retention grooves

cut into it. |

|

The

other AAC type is like in the K&B Sportster. The cylinder

and fins is all one piece and the piston is hard chrome

plated. This type of piston does not have oil retention

grooves but has a hard chrome appearance. |

|

|

|

|

ABC type engines

are intentionally manufactured with a “taper” in

the cylinder so you will feel a "binding” when the

piston is moving through the top of its stroke. You may also

detect what seems like a dead spot or disconnected feeling

of the crankshaft and you may even hear a clicking sound when

the piston is at this point.

These feelings

and sounds are the result of the taper (binding) in the cylinder

affecting the required clearances in the connecting rod ends.

All of these conditions are normal.

As the ABC type

engine obtains operating temperature the cylinder becomes

straight and the clearances between the piston and cylinder

become correct. The straightening is due to the top of the

cylinder running at a higher temperature than the bottom,

thus the top expands more.

It is also normal

for compression to sometimes feel poor when the engine is

stopped and turned over while still hot. This is due to the

piston cooling faster than the cylinder. If the engine temperature

is allowed to stabilize the compression will return to normal.

ABC type engines

must be broken in properly. Click

here to learn how.

|

|

|

|

|

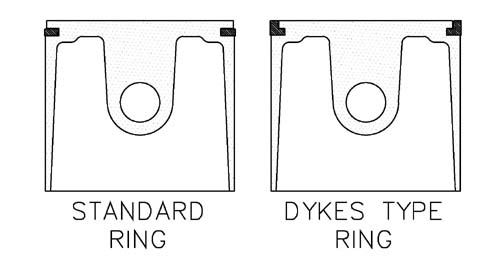

There

are two basic ring types for model engines, DYKE'S and CONVENTIONAL

|

|

A

DYKE'S type ring is a "L" shaped ring that fits

at the very top edge of the piston.

Many people can not even see it as there is no piston material

above it. Dyke's rings do not feel like they are working (no

compression) when the engine is turned over by hand. A dyke's

type ring is pressure activated, (it is like a dyke) when

pressure pushes against the inner side of the ring it is pushed

out tightly to the cylinder wall. When it is running past

the ports no pressure is pushing it so there is less friction.

This is why dyke's rings produce more power than conventional

type rings.

|

|

|

|

A

conventional ring is just that. It has a rectangular profile

and fits into a groove usually about a 1/16" down from

the top of the piston. Conventional rings, when broken in

properly, provide a good seal at any speed. Conventional rings

have constant tension that force them against the cylinder.

When you flip a good conventional ringed engine over it feels

great with snappy compression.

|

|

|

|

|

| A lapped engine

has a steel liner and an iron piston that are lapped together

to a perfect fit. When you flip a lapped engine over you will

feel a perfect seal and good snap of compression. |

|

| These type of piston/cylinder

sets are matched and can not be purchased separately. |

|

| Lapped engines must

be broken in properly. Click

here to learn how. |