|

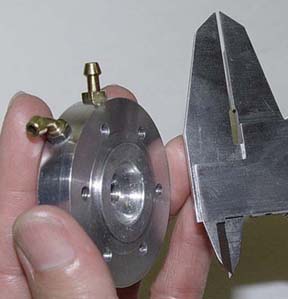

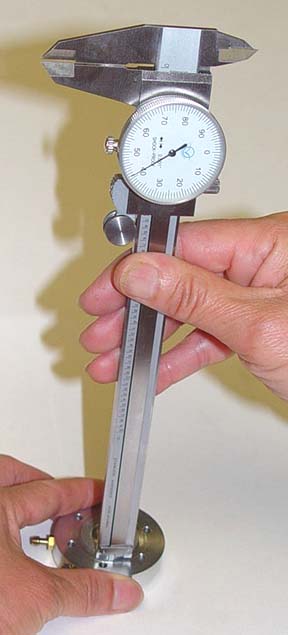

Using the calipers

in this manner will provide an accurate comparison if your

caliper is older or of lower quality.

A note on cheap

or junky calipers. If you measure both the depth of the piston

in the cylinder and the protrusion of the head in the same

fashion (the same end of the calipers), it actually doesn't

matter if the caliper zeros properly. Our result will be the

difference between two measurements, so if both measurements

are off .003" the result will be the same.

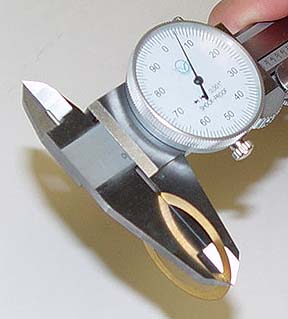

Here our example

again measures .041"

Now do the math...

.062-.041= .021

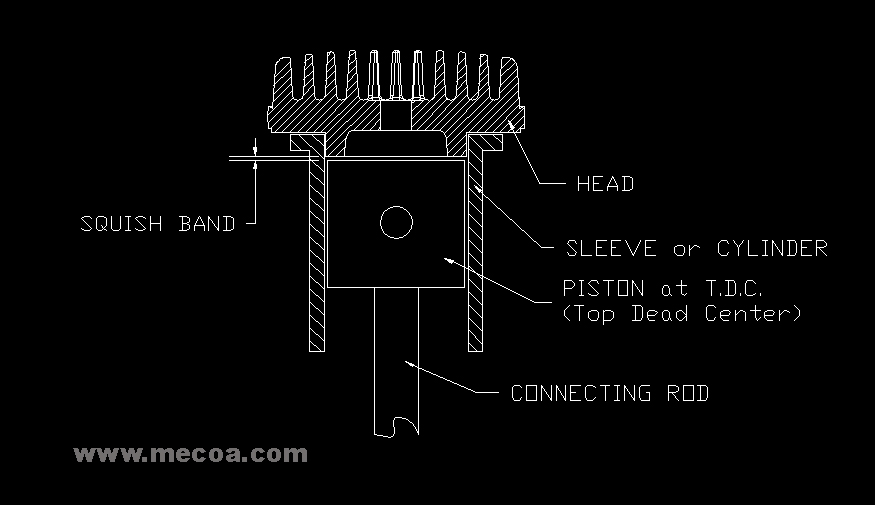

The squish band

is usually set between .016" and .022"

This at the upper

end of the squash band width and the lower end of the compression

spectrum and since this is a larger engine .021 is a good

setting. No head shim is required. This setting can vary with

Nitro content of fuel, exhaust systems, and air density. See

also compression

ratio

|