|

|

|

Ringed

Engines

|

|

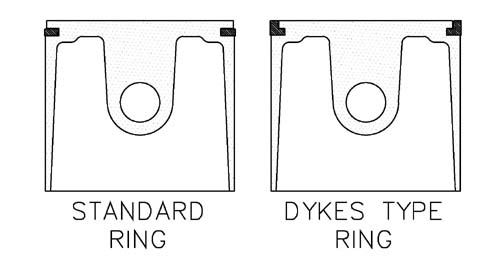

There

are two basic ring types, DYKE'S and CONVENTIONAL

|

|

A

DYKE'S type ring is a "L" shaped ring that fits

at the very top edge of the piston. Many people can not even

see it as there is no piston material above it. Dyke's rings

do not feel like they are working (no compression) when the

engine is turned over by hand. A dyke's type ring is pressure

activated, (it is like a dyke) when pressure pushes against

the inner side of the ring it is pushed out tightly to the

cylinder wall. When it is running past the ports no pressure

is pushing it so there is less friction. This is why dyke's

rings produce more power than conventional type rings.

|

|

|

|

A

conventional ring is just that. It has a rectangular profile

and fits into a groove usually about a 1/16" down from

the top of the piston. Conventional rings, when broken in

properly, provide a good seal at any speed. Conventional rings

have constant tension that force them against the cylinder.

When you flip a good conventional ringed engine over it feels

great with snappy compression.

|

|

|

| |

|

|

|

|

The

above information is provided as a guide. Since MECOA/K&B has

no way of determining the ability of the individual using and understanding

this information, we assume absolutely NO RESPONSIBILITY for any

damage to person or property from the use of this information.

|

|

|

| |

©

Model Engine Corporation of America, All rights reserved.

MECOA

and K&B are Registered Trademarks of Model Engine Corp. of

America

Registered U.S. Patent Office

Linking

to this page is permissible, However no part may be reproduced

without written permission from

MECOA -- P.O. Box 5 -- Sierra Madre, CA 91025 U.S.A.

|

|

|

|

|